New strategies for the refrigerator in the transition towards a circular economy

Fiore, Eleonora (2018) New strategies for the refrigerator in the transition towards a circular economy. In: Proceedings of RSD7, Relating Systems Thinking and Design 7, 23-26 Oct 2018, Turin, Italy.

Preview |

Text

Fiore_New_2018.pdf Download (1MB) | Preview |

Preview |

Text

Fiore_Slides_2018.pdf Download (2MB) | Preview |

![Fiore_MindMap)Fiore_2018.jpg [thumbnail of Fiore_MindMap)Fiore_2018.jpg]](https://openresearch.ocadu.ca/2702/3.hassmallThumbnailVersion/Fiore_MindMap%29Fiore_2018.jpg)  Preview |

Image

Fiore_MindMap)Fiore_2018.jpg Download (410kB) | Preview |

Abstract

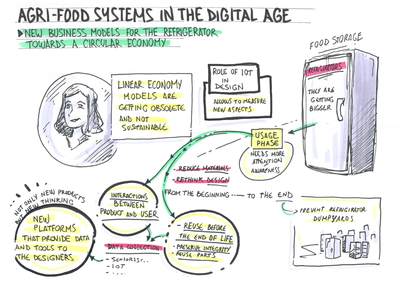

In the last decade, the values of the traditional economy have been strongly challenged, considering the concept of development of the last century as the main cause of many environmental issues that we are facing today. Recently, new strategies have been introduced to provide a renewed concept of development, including the creation new business models in the context of the circular economy, a greater importance of intangible value, the merging of products and services (de Arruda Torresa, 2017) as successful strategies to oppose the classical economy. Nevertheless, both designers and companies still consider projects as ‘finished’ at some point. In the same way in which, before the introduction of waste regulation, manufacturers paid scant attention to their products’ end-of-life, today many companies seem no longer interested in their products after the sale once they have been sold and the warranty has been expired, i.e. while the product is in use. However, the usage phase impact more in products such as the refrigerator, which is characterised by a long lifespan (according to Bakker at al., 2014 the ‘optimal lifespan’ of new purchases is now estimated around 20 years) and a continuous use (400-1100 KWh/y according to the related energy class).

In this paper, instead, we take into consideration how products could continuously evolve after their implementation (Hansen et al., 2008) and how companies could benefit from them throughout their life cycle, delivering new services while changing their business model completely. This approach leaves room for addressing every step of the traditional life-cycle in a more circular way, shifting the focus on a more complex vision about the product. This scenario could radically change by introducing new business strategies such as reducing product ownership through sharing, remanufacturing activities and so forth, while extending the product lifespan, without the need to rely on outdated strategies such as planned obsolescence or the push on the purchase of more goods.

We adapted some of the strategies of the circular economy listed by Kirchherr et al. (2017) within the standard life cycle of the product, by facing the gap of a certain lack of circular strategies related to the use phase (Figure 1). Hence five strategies have emerged, three of which are suitable for exploring new scenarios based on the concept of flexibility and two strategies based on the idea of predictive maintenance.

Product flexibility

This section provides three non-inclusive examples of exploring new scenarios based on flexibility, empower the user to personalise the object and develop new behaviours of use and consumption.

− Reduce ownership: A first scenario could be the integration of a pay-per-use and sharing strategies that leads the user to reduce the ownership of goods, by paying for the actual product use, saving money when the product is used in a virtuous way. In this paper, an in-depth analysis of scenario is carried out, based on the literature which considers ownership and planned obsolescence as two obsolete strategies.

− Product evolution: Software update is just an example of a product that evolves over time, changing and adapting to technological changes. What if the same concept would be extended to every part of the product and every step of the lifecycle? In this scenario, the user purchases/rent a product and then he/she could transform and shape it according to his/her needs with components and functions that can be integrated.

− Product adaptability: What if the product would change its behaviour according to contextual factors, usage information and the habits of those who use it? In this scenario, the user purchases/rents a product, he/she starts using it and after a while his/her expectations will be delivered, because the product evolves to meet user’s requirements. Equipping products with intelligence makes them adapt and respond to change and remain fit-for-purpose over longer time periods (McAloone and Pigosso, 2017; Ellen MacArthur Foundation 2015). IoT data can be used to improve current products, but also for developing virtual services and sharing economy platforms to support the technical lifetime.

Predictive maintenance

The second part of the paper investigates how to combine IoT data with the design of new products, suitable for addressing other parts of the lifecycle. McAloone and Pigosso (2016) suggested that combining IoT data with participatory tools IoT could be one driver for the success of the circular economy, together with sustainable design/eco-design and Business model innovation. The circular economy can benefit from this intelligence for up-cycling processes, monitoring the condition of individual components or whole product systems. Data about the real use of a product can be collected for a short time, with an object instrumented ad hoc for the experiment or alternatively on the marketable products.

Monitoring experimental products: in the first case, the product or its components can be monitored with experiments, to make their recovery suitable for a second valuable use. The R&D or design team, indeed, could study a prototype and then make projections over time of the expected use to determine when the object should be replaced or updated to obtain the maximum value from it. This could be the case of the following three examples, considering:

• Functional groups of components, i.e. a system of parts grouped by a specific function;

• Essential components, whose breakup will compromise the whole product functioning, eventually leading to replace it;

• Wearing parts, which can be easily replaced. Some relevant indicators should be defined and verified by measuring them through ad hoc experiments on these components, providing a more precise knowledge of the system.

Monitoring the final product: monitoring some parameters of the refrigerator as a form of predictive maintenance could also be performed on real products, to provide added value services throughout the lifecycle. It could be done by introducing a few sensors on the final product that will be delivered to the user, to allow continuous data transmission of the most important indicators. Among the possible outcome, detect failures in advance, notify, inform, communicate are only a few possibilities and it raises the need for learning systems able to recognise patterns, together with a platform on which to share and communicate directly with the user.

These two scenarios have different purposes.

The first deal with instrumented objects used for testing and monitoring objects to intercept the product to the suitable time in which it could be fully exploited, before it reaches its end of life, avoiding the product disassembly by preserving its integrity. The second aims to reconfigure the product to obtain real-time data and intervene promptly, shaping the object behaviour on the user habits and behaviour (i.e. by interacting with the user, facilitating the predictive maintenance, upgrading or replacing parts, improving the product or eventually allowing the product to adapt to changed conditions and learn from users’ usage).

Both scenarios would require analytics to measure and combine data inputs over time (Henne, 2015). The proposed strategies are suitable for both current product-centred economy and a future service-centred one, providing directions for future studies that want to address the extension of the product life cycle, while promoting an efficient use of products. IoT data open a variety of possibilities in monitoring, accessing more precise knowledge of goods and households, useful for design purposes.

| Item Type: | Conference/Workshop Item (Paper) |

|---|---|

| Uncontrolled Keywords: | IoT, Predictive maintenance, Circular strategies, Refrigerator |

| Related URLs: | |

| Date Deposited: | 24 Jun 2019 18:56 |

| Last Modified: | 20 Dec 2021 16:16 |

| URI: | https://openresearch.ocadu.ca/id/eprint/2702 |

Actions (login required)

|

Edit View |

Tools

Tools Tools

Tools