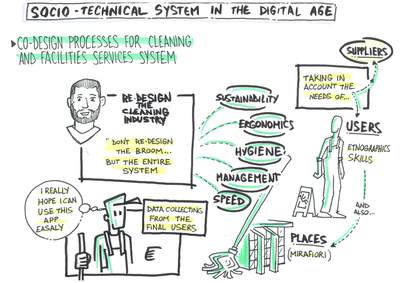

Co-design processes for cleaning and facilities services system

Germak, Claudio, Giuliano, Luca and Abbate, Lorenza (2018) Co-design processes for cleaning and facilities services system. In: Proceedings of RSD7, Relating Systems Thinking and Design 7, 23-26 Oct 2018, Turin, Italy.

Preview |

Text

Germak_Clearning_2018.pdf Download (1MB) | Preview |

Preview |

Text

Germak_Slides_2018.pdf Download (673kB) | Preview |

![Germak_MindMap_2018.jpg [thumbnail of Germak_MindMap_2018.jpg]](https://openresearch.ocadu.ca/2703/3.hassmallThumbnailVersion/Germak_MindMap_2018.jpg)  Preview |

Image

Germak_MindMap_2018.jpg Download (378kB) | Preview |

Abstract

The paper illustrates a co-design research project performed with different stakeholders who represent a cleaning system consortium for the cleaning contract market sector, with the scope of social inclusion and creation of a sample of what Micheal Albert defines as participatory economics [1]. Today, the cleaning market sector is very prosperous and competitive, considering the purpose of efficiency necessarily mindful, at the single company level. Industries involved in this innovation process, in many cases offers not only services related to cleaning tasks but logistic and furniture services also (i.e. management, security, and training). In particular, those industries work in the contract market sector for big environments (i.e. hospitals, schools, industries) where hygiene standards are very high, and the commitments demand a high degree of quality and innovation through very selective invitation to tenders.

Commonly, the companies belonged to this market sector work in four main directions:

1- research and development of innovative and sustainable hygiene solutions

2- integrated and computerised management of cleaning and logistics services

3- speed up and optimisation of cleaning operations

4- ergonomics of cleaning equipment.

To the operational teams on site, meaning the workers settled in the cleaning site, are given particular attention, both in economic terms because they are the principal source of costs for the company and in training terms, because of the lack of professional skills in some worker category. However, for the future, a paradigm shift is forecasted. It is thought that this significant market sector will be able to absorb, even temporally, exodised workers also, namely that one expelled in the middle of their age from the employment market; surely with a high cultural level and familiarity with digital technologies.

Referring to this scenario, a famous Italian cleaning system group has started the research project described in the paper and based on the SMART PRODUCTION 4.0 industry model “… new production technologies shared by production-related actors that foster collaboration between people, machines and systems.” [2] In this first step of the experimentation, a SMART SERVICE is described. As reported by Consulting o McKinsey, SMART SERVICES consist in “a new generation of information and technical infrastructures that helps manage and monitor systems, exploiting the logic of maximum integration between all the actors of the production chain, including customers “. [3] The reference to the principles of Industry 4.0 is a requirement for our research because they are revolutionary towards the way of manufacturing products and organising work according to a systemic logic:

• Automated and interconnected production models;

• Intelligent and communicating products;

• Traceability of processes that fosters collective information;

• Shared and collaborative production model at the supply chain level;

• Cloud storage of a significant amount of collected data and their accessibility.

The cleaning system group, in particular, has requested to the University Design team, skilled in the development of ICT based services, HCD and Interaction Design, to direct the project by identifying the virtuous relationships among actors, processes and tools to implement them systematically in the supply chain of cleaning activities. Therefore, the project framework consists of two ambits of work, the first one consisting of the cleaning site in which people are living the spaces (users), cleaning operators and team coordinators collaborate, and the second one external to the cleaning site, consisting of service companies, distributors and manufacturers producer. The co-design chain created in this way involves all the different actors in one single process, each with its role, personal problems, needs and behaviour [4]. Employing UCD User-Centered Design techniques, the human being has been placed at the centre of the design process; the result is a new process system structured by new generation of APPs and Big Data Management platforms. Figure 1 describes the new process diagram highlighting how different actors can communicate each other, report malfunctions or issues, convey needs and provide data that the system collects and transforms into inputs, in order to make:

• the cleaning and maintenance process participated among final users, operators and cleaning system consortium;

• the control of cleaning services and the maintenance of spaces more effective and efficient, thanks to the real-time communication of issues between the user, operator and cleaning supervisor (coordinator);

• the cleaning company more aware of energy consumption, the effectiveness of the materials used (consumer products and equipment) and the efficiency of its workers;

• the production of products and equipment more sustainable developed for reducing the fatigue and increasing safeguarding the health of workers and the environment.

| Item Type: | Conference/Workshop Item (Paper) |

|---|---|

| Uncontrolled Keywords: | Sustainable Fashion, Big Data, Systemic Innovation Design, Information flow |

| Related URLs: | |

| Date Deposited: | 25 Jun 2019 15:07 |

| Last Modified: | 20 Dec 2021 16:16 |

| URI: | https://openresearch.ocadu.ca/id/eprint/2703 |

Actions (login required)

|

Edit View |

Tools

Tools Tools

Tools